Safety first

Many of our tools are also available with protective insulation for working on electrical systems. These tools naturally comply with all safety standards and offer you the protection you need when working with electrical voltages.

Product highlights

Always up to date – We're constantly developing our product portfolio. So that we can support you in your work and your projects in the best possible way.. And to make your decision even easier, we regularly have attractive promotions for you. Do you already know these current highlights from our range?

What are 1000 V tools?

- With protective insulation, tools have special protective insulation and must be tested in accordance with IEC 60900.

- The standard also stipulates labelling with the manufacturer's name, the model and Article No. and the year of manufacture.

- With protective insulation, tools can be recognised by the "double triangle" logo and the 1000 V specification.

- All requirements set out in DIN ISO, e.g. torque, impact and hardness, must be achieved and complied with.

Special HAZET 1000 V protective insulation

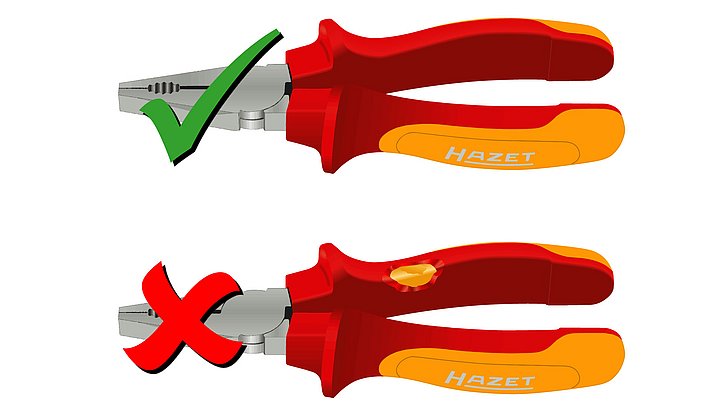

- With protective insulation, HAZET tools generally have a two-colour multi-layer safety insulation, i.e. a red insulation layer on the outside and a yellow insulation layer on the inside. This design supports the building regulations BGV A3 (VBG-4)

- The insulation must not be visually damaged. If the inner yellow insulation layer is visible anywhere, the tool must be disposed of immediately as there is a risk of electric shock. Live working is no longer possible and is life-threatening.

- With protective insulation, tools whose insulation has been technically sprayed on only have a single layer of red insulation. For safety reasons, the user should therefore check that the insulation is intact before starting live work to ensure their safety.

Things to know before working with 1000 V tools

- Here are some Safety precautions for your own protection and safety:

- All work involving live electrical systems may only be carried out by qualified personnel

- Only tools and equipment labelled with the "double triangle" and "1000 V" icons are permitted (see also BGV A3 building regulations)

- Always check that the insulation is undamaged before starting work

- Dispose of damaged tools or ensure that they are no longer used for live work

- Observe the regulations of trade associations etc. and / or power supply companies

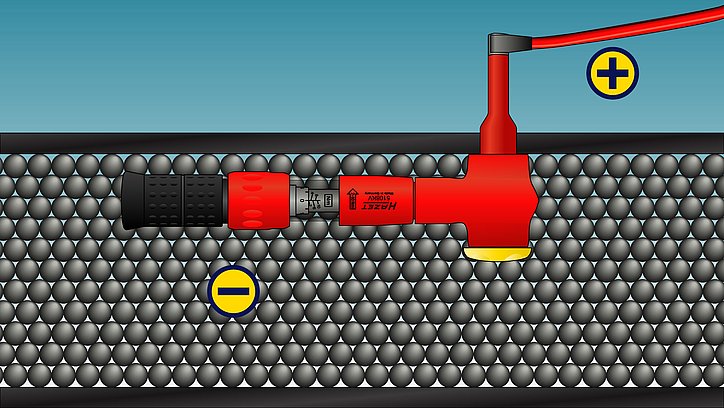

- HAZET 1000 V tools guarantee safe and hazard-free work up to 1000 V AC (alternating voltage) and 1500 V (direct voltage)

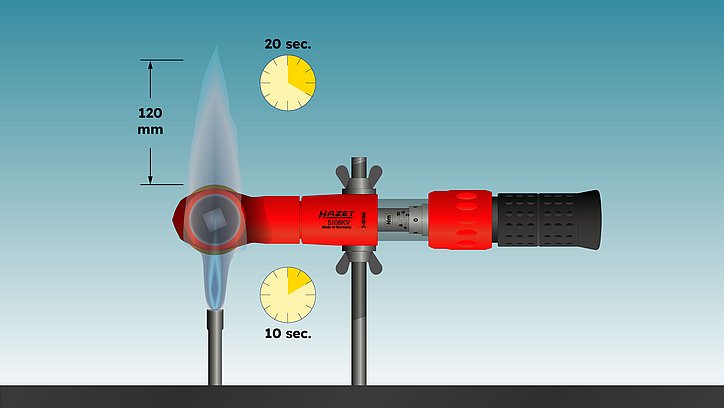

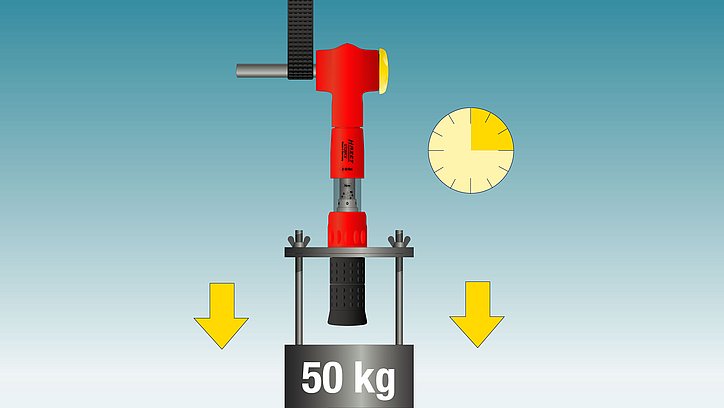

Impact test at low temperature [type test]:

With a dwell time of 2 hours at an ambient temperature of -25°C, the insulation must not show any cracks or other damage when subjected to targeted impacts and shocks (drop height 0.6 m).

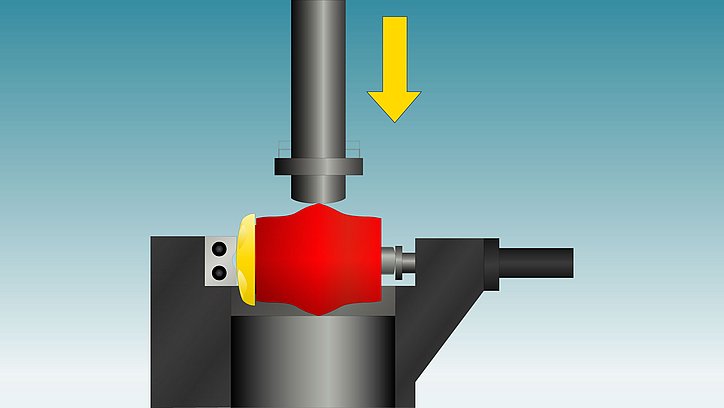

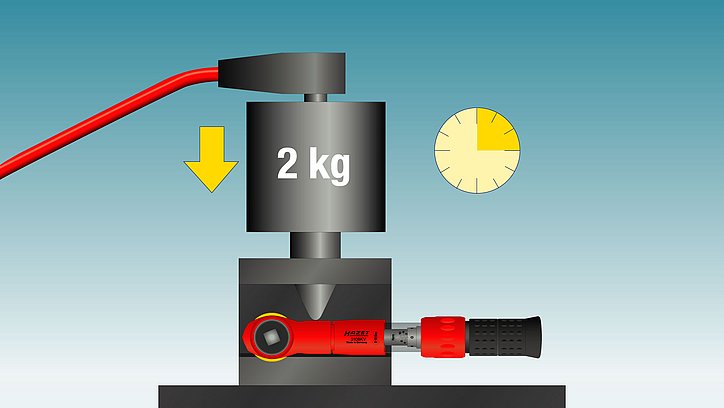

Impact test at ambient temperature:

At an ambient temperature of 23°C, the insulation must not show any cracks or other damage when subjected to targeted blows and impacts (drop height 2m)