Service begins with a capital S

We not only attach great importance to the quality of our products. But also to our service. We're your direct contact when it comes to all aspects of maintenance, adjustment, calibration and complaints handling for our torque products.

Essentially, our Service Team offers you

• Repair, adjustment, calibration and certification of HAZET torque wrenches

• Scheduled service tasks for HAZET torque wrenches

• Short response times

• Test equipment monitoring service for torque wrenches

• Contact for service matters

Repairs

If a repair is required, you can send your torque wrench to us. We then carry out an inspection to determine the necessary repairs. Our inspections take into account both technical and economic factors. If these repairs are invoiced, you will receive a cost estimate in advance.

You can also purchase some spare parts, such as internal ratchet parts, from our Spare Parts Shop.

Various repairs then require recalibration. This means we don't offer all spare parts for free sale.

Torque tools

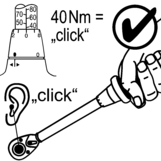

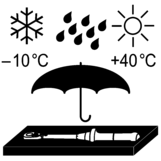

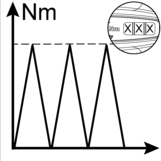

Our recommendation for the test/calibration interval is based on the DIN EN ISO 6789:2017 standard for torque wrenches, which recommends recalibration after one year, after 5000 loads or after every overload. The inspection intervals must be shortened in case of increased quality and safety requirements or intensive use. The calibration interval is specified by the user, as he is responsible and knows the use of the test specimen.

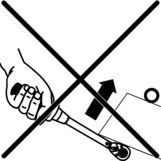

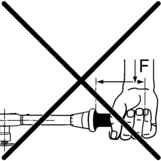

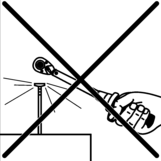

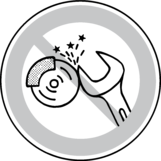

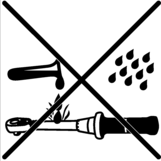

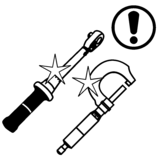

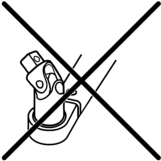

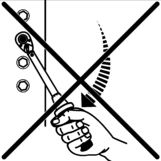

The torque wrench is a measuring instrument that should not be misused. Other tools such as the HAZET 6396 or 6397 tool holders or an impact wrench are better suited for loosening.

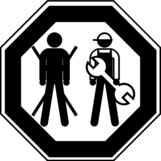

HAZET only tests, adjusts, repairs and certifies torque wrenches that they manufacture.

Training offers

In addition to familiarity with DIN EN ISO 6789, the adjustment, calibration and repair of torque wrenches also requires more detailed knowledge of the structure and function of the torque wrenches. The training offered in our modern training centre "HAZET Welt" gives you the opportunity to gain this knowledge.

If required, simply ask us for the next dates.

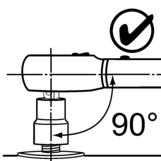

SYSTEM 6004CT ∙ 6005CT:

Attention! Direction of rotation left without torque limitation

Read operating instructions before use

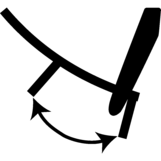

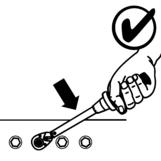

Do not operate the torque wrench jerkily

Calibrated direction of rotation (clockwise) Release torque = set value

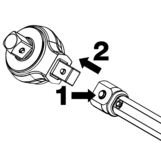

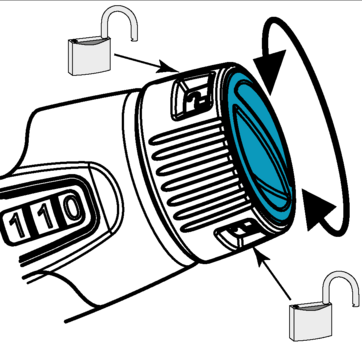

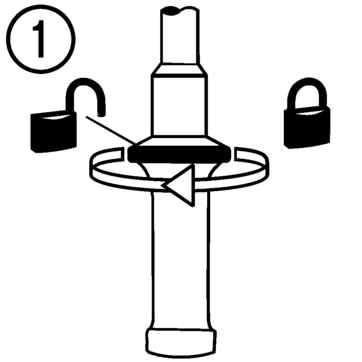

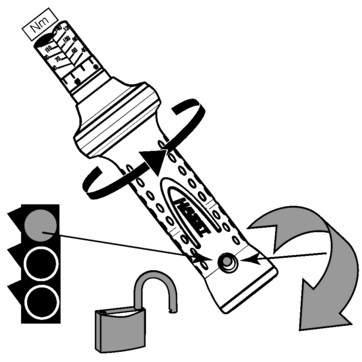

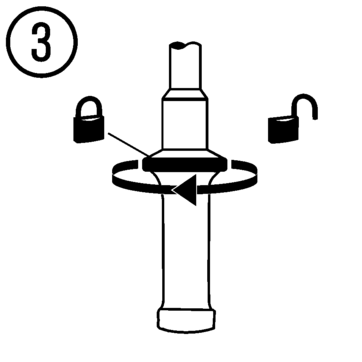

SYSTEM 5000-3CT – Unlock (1)

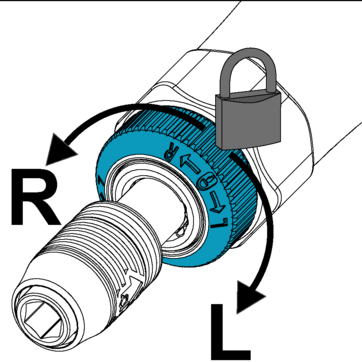

Turn the safety lock to the left ←

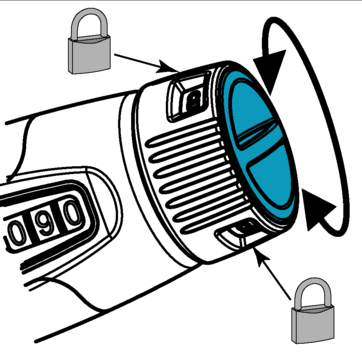

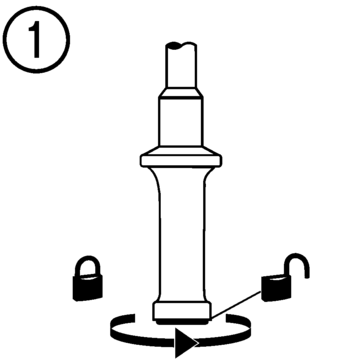

SYSTEM 5000CLT ∙ 6000 ∙ 6000CT – Unlock (1):

Turn the safety lock to the right →

SYSTEM 5000CT ∙ 5000-2CT – Unlock (1):

Turn the safety lock to the right →

SYSTEM 6000CT (6130 – 6296-1CT) – Unlock (1):

Turn the safety lock to the right →

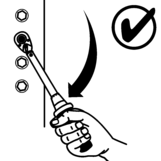

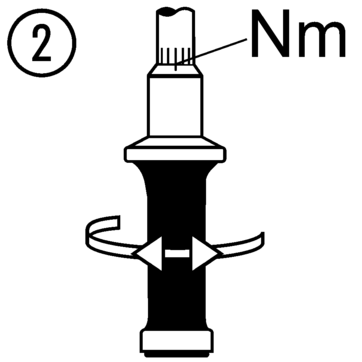

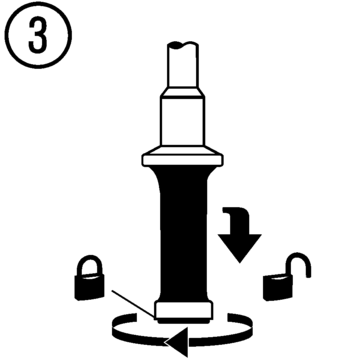

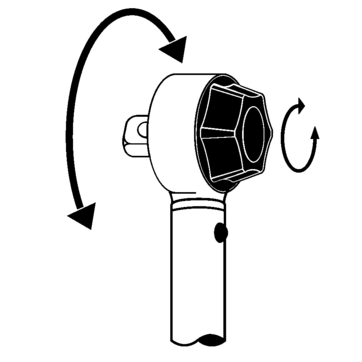

SYSTEM 5000CT ∙ 5000-2CT – Set (2):

Set the desired torque by turning the handle.

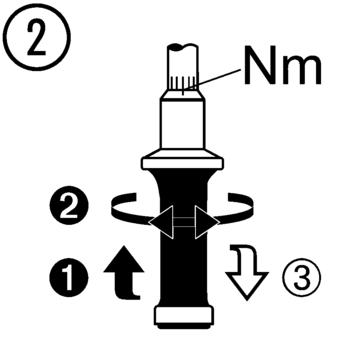

SYSTEM 5000CLT ∙ 6000 ∙ 6000CT (6106-1CT – 6282-1CT) – Set (2):

Slide the handle forwards and turn the handle in this position until the desired value is reached

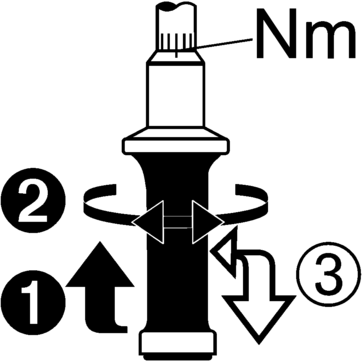

SYSTEM 6000CT (6130 - 6296-1CT) – Set (2):

Set the desired torque by turning the handle

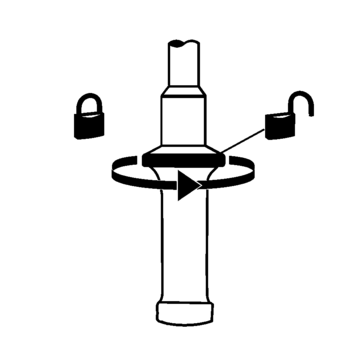

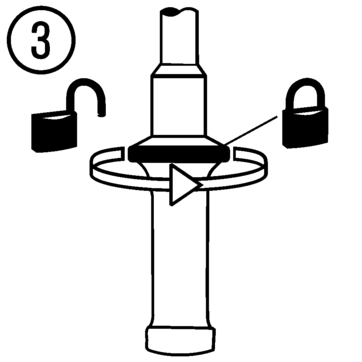

SYSTEM 5000-3CT – Fix (3):

Turn the safety lock to the right →

SYSTEM 5000CT ∙ 5100-2CT – Fix (3):

Turn the safety lock to the left ←

SYSTEM 5000CLT ∙ 6000 ∙ 6000CT (6106-1CT – 6282-1CT) – Fix (3):

The fixation is released automatically when you let to of the handle.

Secure by turning the safety lock to the left ←.

SYSTEM 6000CT (6130 – 6296-1CT) – Fix (3):

Turn the safety lock to the right →

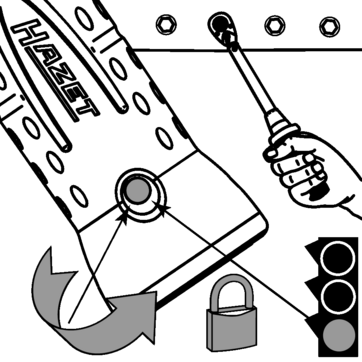

SYSTEM 5000CT – Direction of actuation:

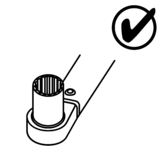

Select the direction of actuation by changing the square drive

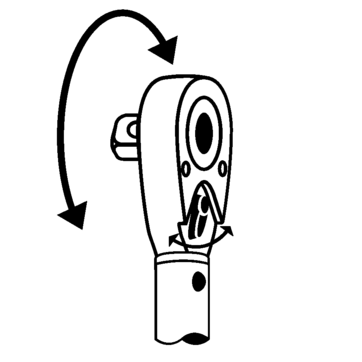

SYSTEM 5000-2CT ∙ 5000CLT ∙ 6000 ∙ 6000CT (6106-1CT – 6282-1CT) – Direction of actuation:

Select the direction of actuation by adjusting the shift lever

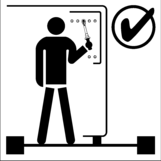

Contact Service Centre

Phone +49 (0) 21 91 / 7 92-355

service-center@hazet.de

Service times:

Monday to Thursday 7:00 a.m. to 3:30 p.m

Friday 7:00 to 13:00

Postal address:

HAZET-WERK

Service Centre

Güldenwerther Bahnhofstraße 17

42857 Remscheid